Global technology company UST has partnered with Kaynes Semicon, a subsidiary of the established electronics manufacturing services provider Kaynes Technology, to establish a joint venture that will set up a state-of-the-art Outsourced Semiconductor Assembly and Test (OSAT) facility in Sanand, Gujarat. The initiative marks a significant milestone for India’s growing semiconductor industry and is poised to play a significant role in the country’s drive for electronics self-reliance.

Sanand Chosen for Landmark Semiconductor Facility

Sanand, already a prominent automotive and electronics manufacturing hub in Gujarat, was selected for its robust infrastructure and industry-friendly government policies. The upcoming facility will focus on providing advanced OSAT services, including assembling and testing chips used in automotive, industrial, and consumer electronics.

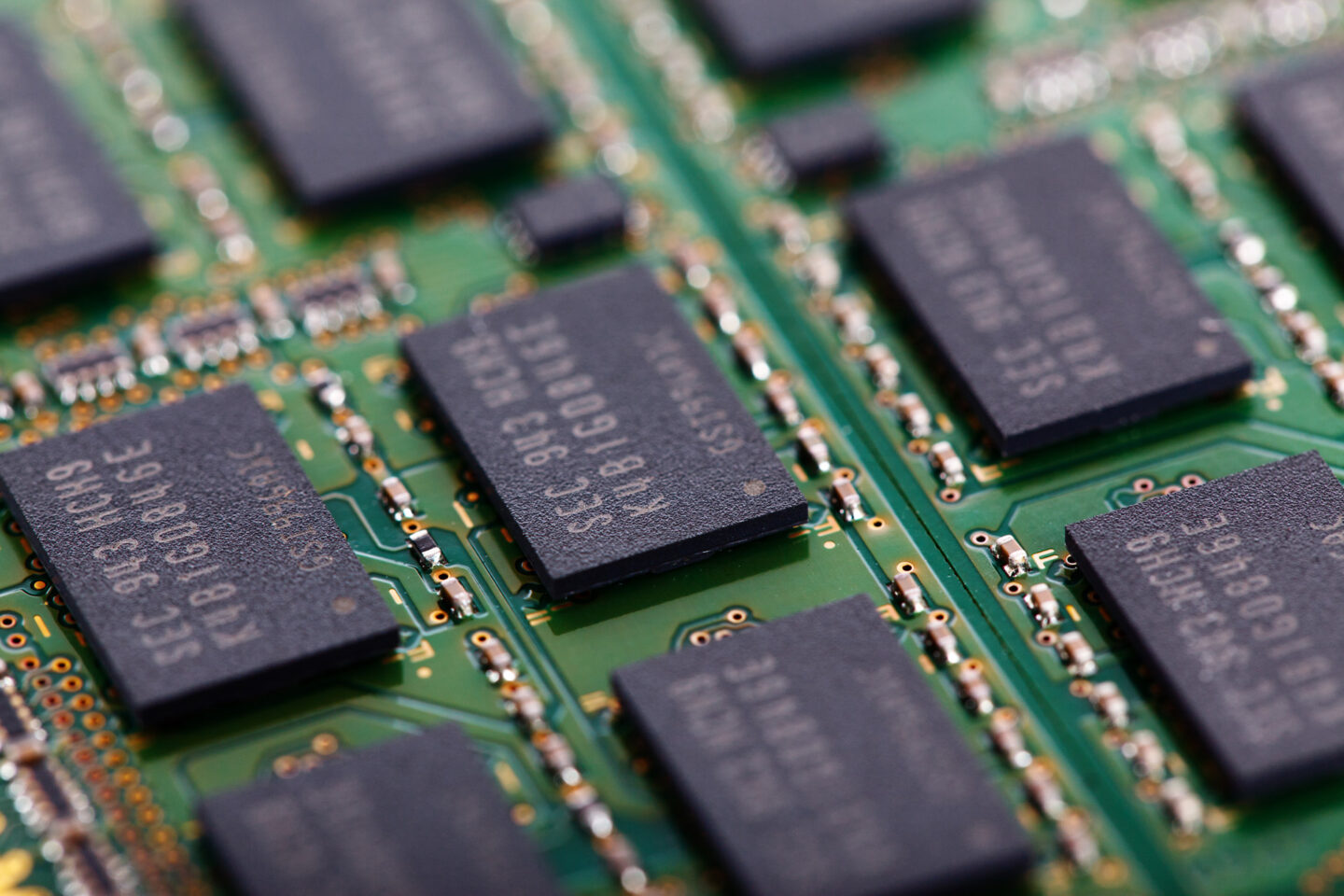

Initial plans centre on memory packaging, logic devices, and microcontroller units, with capacity and complexity to be scaled up as the plant matures. The facility is expected to feature cleanrooms, test laboratories, and highly automated assembly lines constructed to stringent global standards.

Investment, Timeline, and Collaborators

The new plant involves a total investment of ₹3,330 crore (approximately $400 million) and will be developed over multiple phases, starting with immediate land acquisition and civil works. Construction is expected to commence in early 2025, and the first phase of production is anticipated by late 2026.

Kaynes Semicon will bring specialised local manufacturing and operational know-how. At the same time, UST’s expertise in technology and global markets will help position the joint venture for exports as well as domestic supply chains.

The plant is projected to create more than 500 direct skilled jobs and is expected to generate significant additional employment through auxiliary and support services.

Implications for Gujarat and India’s Semiconductor Mission

This OSAT facility not only cements Gujarat’s standing as a sought-after hub for high-tech manufacturing but also aligns squarely with India’s Semiconductor Mission and the government’s targeted Production Linked Incentive (PLI) schemes.

Building indigenous OSAT capacity addresses a critical gap in India’s semiconductor ecosystem, allowing chips designed or fabricated abroad or domestically to be packaged and qualified within India, thereby reducing dependence on foreign contractors and bolstering supply chain security. This project is expected to accelerate private investment in India’s emerging silicon ecosystem and support the broader ambition of making India a global leader in electronics and semiconductor manufacturing.